Site founded September 1, 2000, passing 300,000 page views in January 2005

These home pages remain free of any charge. We need donations or subscriptions/gifts for students, military and family. Please pass on this website link to your family, relatives, friends and clients.

|

|

of History & Folklore

Subscribers Edition Stories & Photos

The most in-depth, comprehensive site about the Skagit.

Covers from British Columbia to Puget sound. Counties covered: Skagit, Whatcom, Island, San Juan. An evolving history dedicated to the principle of committing random acts of historical kindness

|

Noel V. Bourasaw, editor  810 Central Ave., Sedro-Woolley, Washington, 98284 810 Central Ave., Sedro-Woolley, Washington, 98284

Home of the Tarheel Stomp  Mortimer Cook slept here & named the town Bug Mortimer Cook slept here & named the town Bug

|

|

Skagit Steel and the McIntyre family, part 2

By Jack Keller and E.A. Perdue, The Washingtonian Magazine,

February 1929, "a state magazine of progress"

|

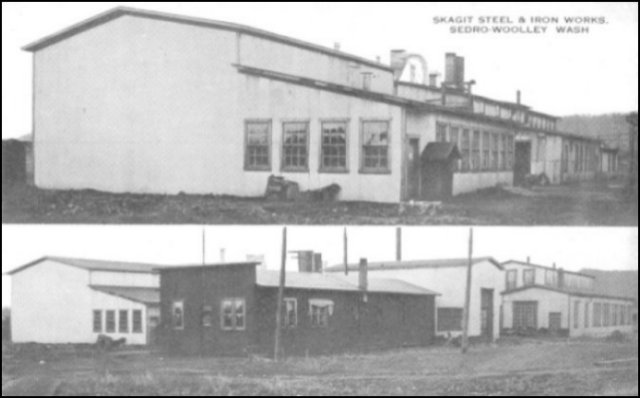

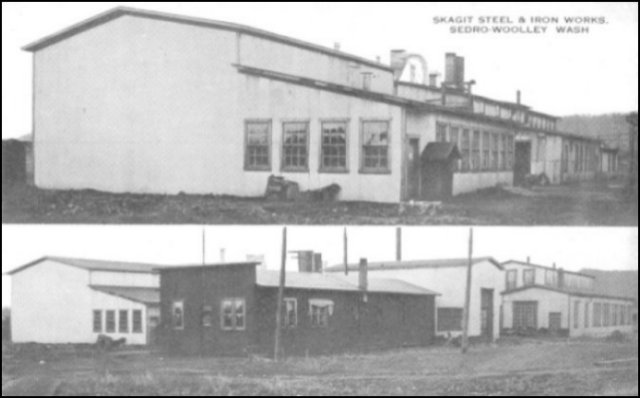

These photos of Skagit Steel & Iron Works are from a postcard printed in the 1920s. They show the new plant built in 1910 after the fire at the original Puget street foundry. By the time of these photos the McIntyre family had full control of the plant and they had made it a manufacturing facility as well as a repair shop for logging camps and local logging railroads. David G. McIntyre and his son Sydney had expanded production greatly from the early days, Sydney was patenting inventions and sales had spread around the world. Gas-driven donkey engines in the M.A.C. product line had revolutionized logging.

|

Enlarged Skagit Steel project incorporated

Continued from part one

On Nov. 10, 1914, the plant was incorporated under the name of Skagit Steel & Iron Works [hereafter SS&IW], as the original name; Sedro-Woolley Iron Works [hereafter SWIW] no longer indicated the full extent and scope of the business. SS&IW had now assumed such proportions that it was the largest plant of its kind north of Everett. While operating as founders of iron and steel and doing repair work, the possibility of developing into a manufacturing plant had not been considered by the management.

In chronicling the development of this plant, it is necessary to present the men who were responsible for its growth during the years from 1902-17. Listed as they appeared on the scene, these men were: John G. Anderson, founder; F.R. Faller, manager; Frank Fritsch, the latter furnishing one-third of the capital, and David G. McIntyre, shop foreman.

McIntyre spent much of this time around logging camps, repairing locomotives, rustling business and establishing confidence in his company among the men and firms with whom he dealt. For 15 years he held a minority interest and consequently could not put across his ideas concerning the development of manufacturing.

David G. McIntyre and his son Sydney S. McIntyre and Frank Fritsch assumed control of SS&IW in 1917 and soon afterwards purchased the stock of F.R. Faller. In 1918 the McIntyres bought out the interests of the Fritsch family and began making plans for an entry into the field of manufacturing.

Vision of one man developing

Review of the history of every successful enterprise always discloses, in its romance, a man of vision. In this instance the man was David G. McIntyre. With his first job he planned for the day when he would have the opportunity to manufacture products of iron and steel.

When Mr. McIntyre and an older brother left [the town of North Street in] St. Clair county, Michigan, to find work in Chicago, they were facing an uncertain and rather adventurous future. Limited funds and early difficulties in finding work did not discourage them and finally they both found work, David locating in a Chicago machine shop. Later he found employment with the Union Iron & Steel Works, one of Chicago's big manufacturing plants. Here he worked for six years, diligently studying every phase of the factory and acquiring a practical and fundamental knowledge of machinery.

His keen interest never waned and when, after many years of determined and unfaltering effort, he became president of SS&IW, it was indeed the fulfillment of a life's ambition.

It was early in 1902 that Mr. and Mrs. McIntyre left Superior, Wisconsin, to come west, locating first in Port Angeles, Washington. Soon they moved to Skagit county where they settled on twenty-acre tract of logged-off land near Sedro-Woolley.

|

S.S. Sydney McIntyre, 1949

|

Building a home and clearing land was a real task of pioneering and Mr. McIntyre played the lead role as provider, carpenter, land clearer and farmer. After many weeks of hard work the land was cleared, buildings erected and the family was established as real farmers in the fall of 1902. With their little family consisting of David, his wife Clara, and children Sydney, Marjorie and Bernice, aged nine, seven and one, respectively, the McIntyres settled down to the comfortable enjoyment of a well-earned livelihood.

At this time McIntyre went to work for the Sedro-Woolley Iron Works, shortly after its establishment. With two miles to walk to the shop and a nine-hour working day that often extended into long hours of overtime, he was a very busy man. But with a sensible measure of Scotch frugality and determined purpose in mind he was happy because he saw a possibility for materialization of boyhood dreams to own a steel and iron plant. To this plan had later been added the desire that he and his son Sydney might work together and eventually enter the manufacturing field.

Sydney, at 14 years of age, though rather small and short to operate a lathe, was employed during high school summer vacations at the Iron Works. He had plenty of nerve, learned quickly and while working at SWIW during his college vacations served his apprenticeship and became a competent machinist. He spent considerable time in logging camps and after graduating from college, where he studied mechanics and mechanical engineering, he entered the drafting room of SWIW.

Well-laid plans maturing

|

Click on this thumbnail for a full-sized photo of the interior of the Skagit Steel foundry in the 1920s. Berniece Leaf photo.

|

Then came the long-awaited opportunity.

In 1917 the McIntyres had acquired control of the plant. This chance found them ready; the father a machinist with experience in shops and factories and the son unusually adept in mechanical engineering and designing.

During the World War they joined the ranks of firms who held their plant at the call of the war activities. Their manufacturing plans were put aside while plant facilities were devoted to the filling of contracts for several ship building companies in Seattle and Bellingham. This business consisted largely of pinions, rudder parts, mast bands, struts and propeller hubs; many single castings weighed as much as three tons.

Following the armistice and the completion of war contracts, the company turned its attention to manufacturing and bought out the first M.A.C. "4-40" gas rail car. It was designed by Sydney McIntyre and built for the Dempsey Logging Company. This was a 4-cylinder, 40 horsepower car of five tons deck capacity. Its serviceability in hauling large crews and its adaptability to light switching and general work of this nature about logging camps foretold and immediate market demand for cars of this type in supplementing steam locomotives, commonly used for these lighter but none the less necessarily important services about logging operations.

New type of hoist invented

While engaged in the manufacture of these gas rail cars in 1920, the first M.A.C. hoist was designed and patented by Sydney. This all-steel, two-drum donkey utilized the Fordson tractor as its power unit. The surprising speed and power this compact machine was capable of developing indicated its adaptability to any work requiring a powerful hoisting donkey. Though gas donkeys were not used in logging operations prior to the introduction of the M.A.C. hoist, this machine soon made a place for itself in this field. Production necessary to fill demand of rapidly mounting sales taxed the capacity of the factory.

Thus began the first manufacturing of gasoline driven hoisting and transporting equipment wet of the Mississippi. With an accurate foresight of the necessary manufacturing facilities for the future, a factory expansion program was laid out in 1920. Since that time the plant has kept pace with the steadily increased demands for its products; not only in production but also in design that has continued to meet the ever-changing needs of industrial and logging requirements.

Models standardized for service

Backed with a guarantee against defects of materials and workmanship also providing for satisfactory performance on any job passed on by a representative of the company, other equipment was constantly added to the M.A.C. line as proved performance brought the demand. Thirty standardized models of hoists, donkey engines, speeders, rail cars, locomotives and coaches are now on an established production basis, while heavier and more powerful equipment is in process of design.

Hoists that are adapted to Fordson and McCormick-Deering power units and that weigh from 2,250 to 6,350 pounds are employed in a multitude of services in logging and industrial fields wherever a powerful gas hoisting donkey is required. Gas donkey engines for logging and construction work and built in various drum combinations range in power from 20-300 horsepower. Notable among this series are the M.A.C. 100-horsepower, two-speed construction hoists and M.A.C. 170-horsepower, four-speed yarders, the latter being equipped with air friction devices. Still higher-powered gas donkeys, now being designed, soon will be placed on the market.

Speeder enters logging field

|

A 1939 article in the Sedro-Woolley Courier-Times noted that one of Skagit Steel's most notable products starting in the 1920s was the 20-105 horsepower speeder along with diesel rail cars. Earl Hoyt, who married David McIntyre's daughter Marjorie, marketed these products in a specially created Seattle sales office for Skagit Steel. By 1939 the company was designing and manufacturing diesel electric locomotives for Seattle City Light to haul freight and passengers to the dam sites in the North Cascades. Photo from an undated sales promotional flyer.

|

The M.A.C. "4-30" Speeder with a 53-horsepower motor, geared four-wheel drive and five speeds in either direction, is the company's entry in the speeder line. Built for the severe service over logging railroads, this car is capable of surprising performance. It has ample power to handle trailers in addition to its own capacity of 35 seated passengers or a three and one-half tons deck load.

Recently improved M.A.C. "4-40" and "6-60" gas rail cars with 67 and 105 horsepower Buda power units are built for grueling service over heavy grades, severe curves and rough roadbeds characteristic of logging railroads. For hauling large crews, for light switching, freighting, fire patrol, handling supplies and for railway construction work, these cars have a distinguished efficiency in relieving steam locomotives of the bothersome side issues and are widely used on the Pacific Coast, effecting important economies.

Port commissions, numerous kinds of construction projects, private railroads, mills, mines and other industrial enterprises have found these cars useful and valuable for handling he myriad of jobs that must be economically disposed of to give dispatch and systematic order to operations.

Locomotives and gas coaches

Five-ton rail locomotives, Fordson or McCormick-Deering powered and featured with four-speed transmissions, [these units] have unusual speed and flexibility for track hauling and fill requirements of industrial plants, construction projects and are also well adapted to hauling in mines, quarries, mills and yards.

Various models of gas rail coaches have been constructed, ranging from 30-50 passenger models. They were powered with motors of 100-170 horsepower, capable of operating on a 30 mile-per-hour schedule with a maximum speed of 45 miles per hour. M.A.C. coaches are strictly modern in mechanical construction and have late-style fixtures and accommodations.

One of the 170 horsepower coaches, measuring 48 feet in length and having a baggage compartment of 3,000 pounds capacity is now being operated by the Longview, Portland & Northern Railway. The City of Prineville, Oregon, has been furnished with one of the 30-passenger models.

Seeking far-flung markets

Akin in location to the proverbial rattrap manufacturer, the McIntyres have not waited for a path to be beaten to their door. In sharp contrast, however, they have shown the same energy in searching out new uses for their products. Additional sales outlets and representatives insist upon careful construction of each machine and in giving every product strict engineering attention as well as constant refinement by means of all worthy improvements.

Dealers and factory representatives, covering the northwestern states and British Columbia, have placed many hundreds of M.A.C. products. One county in Oregon alone has 65 M.A.C. gas donkeys in operation. Recent entry into foreign markets has resulted in placing this equipment in Alaska, the Hawaiian islands, Philippine islands, Federated Malay States, India and other far off countries.

Equipment assembled in the shops of this northwestern Washington factory is to be found in as remote places as the jungles of Cheat Nair Forest, Olavakott, South Malabar, Madras Presidency and India, where M.A.C. hoists and superintended crews of natives are doing modern high-lead logging.

Meeting competition of elephants

Prior to the fall of 1925, when the chief forest engineer of Chepauk, Madras, procured his first M.A.C. Hoist for what was termed an extraction experiment, elephants supplied the logging power. With all due respect to the powerful elephants, the chief engineer now advises that one M.A.C. hoist "costs no more than one elephants and does the work of ten." [He went to say that] this equipment has been "conspicuously successful in yarding logs in regions so steep that the timber was inaccessible before the advent of the gas donkey."

Skagit Steel & Iron Works, the largest Sedro-Woolley enterprise, has an average annual payroll of $175,000 and employs 125 men, 85 percent of whom are trained mechanics. In 1906 approximately 95 percent of the volume of business consisted of repair and foundry work. Now 80 percent of the business is in the production of M.A.C. gas-driven equipment, which reflects the splendid growth of the company as a manufacturing enterprise.

Men active in home town

Although wrapped up in the manufacturing game, the McIntyres have always given their assistance generously in the support of civic and state improvements. David G. McIntyre has served as both mayor and councilman of Sedro-Woolley. He is a director of the state Chamber of Commerce and has devoted much time to promoting the Cascade Highway, having been president of the highway association since he launched the movement for completion of this east-west highway across northern Washington.

Sydney McIntyre, whose advice is much sought in connection with local affairs, is serving as city councilman. His time, however, is well occupied as vice president and general manager of the company and he has found in his business a large-sized job. He is recognized in mechanical engineering and manufacturing circles for his resourcefulness in invention and design.

[Ed. note: this magazine was doing very well when this article was published, but that was just eight months before the crash of the stock market. We have not found a trace of it anywhere except for the copy that Berniece Leaf loaned. We hope that a reader might know more about this interesting magazine.]

Continued in ">part 2 of the 1929 article: Skagit Steel is born, 1914-29. And then read our exclusive profile of David G. McIntyre and his pioneer family

Story posted on xx

Did you enjoy this story? Please consider subscribing to the optional Subscribers Edition. That is how we fund this grand project.

Please report any broken links or files that do not open and we will send you the correct link. Thank you.

|

You can read about our prime sponsors:

Read the history websites of our sponsors and supporters, who help fund research of local history:

Heirloom Gardens Natural Foods at 805B Metcalf street, the original home of Oliver Hammer.

Oliver Hammer Clothes Shop at 817 Metcalf street in downtown Sedro-Woolley, 82 years.

Bus Jungquist Furniture at 829 Metcalf street in downtown Sedro-Woolley, 36 years.

Schooner Tavern/Cocktails at 621 Metcalf street in downtown Sedro-Woolley, across from Hammer Square.

Peace and quiet at the Alpine RV Park, just north of Marblemount on Hwy 20

Park your RV or pitch a tent by the Skagit river, just a short driver from Winthrop or Sedro-Woolley.

Would you like to buy a country church, pews, belfry, bell, pastor's quarters and all? Email us for details.

|

|

|

Did you find what you were looking for? If not, please email us and tell us what you seek and we will put it on our list to research. The more details, the better.

|

Please sign our guestbook so our readers will know where you found out about us, or share something you know about the Skagit River or your memories or those of your family. Share your reactions or suggestions or comment on our Journal. Thank you for taking time out of your busy day to visit our site.

|

Sign Our Guestbook

View Our Guestbook

|

Remember, we welcome correction and criticism. Please click on the email slot at the right to report any problems with these pages or to suggest ideas for future stories. This is a completely free site. We fund it by providing an online magazine for paid subscribers. If you are not already a subscriber and you would like to help support our considerable research costs, you can subscribe for just $20.00 per year. As a paid subscriber, you will receive eight yearly issues plus many rare treats between times, including scans of photos and documents that illustrate local history, before they are shared with anyone else. You can go here for Subscription details and you can read the preview edition to see examples of our in-depth research. You may also order gift subscriptions for friends, family or clients who are interested in local history or students or military people who are away from home. Or you can email us for more details. Do you have scanned photos to share? Or you can mail us copies. See addresses to right.

|

Email us at: journal@stumpranchonline.com

Mail copies/documents to street address: Skagit River Journal, 810 Central Ave., Sedro-Woolley, WA, 98284.

|

810 Central Ave., Sedro-Woolley, Washington, 98284

810 Central Ave., Sedro-Woolley, Washington, 98284